Brief introduction:

What is Cu-W alloy? Cu-W alloy is short for Tungsten Copper Alloy. The copper content is 10%~50% in Cu-W alloy. Our Cu-W Alloy is produced by Impermeable Method.

Copper–tungsten (tungsten–copper, CuW, or WCu) is a mixture of copper and tungsten. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The microstructure is therefore rather a metal matrix composite instead of a true alloy.

The material combines the properties of both metals, resulting in a material that is heat-resistant, ablation-resistant, highly thermally and electrically conductive, and easy to machine.

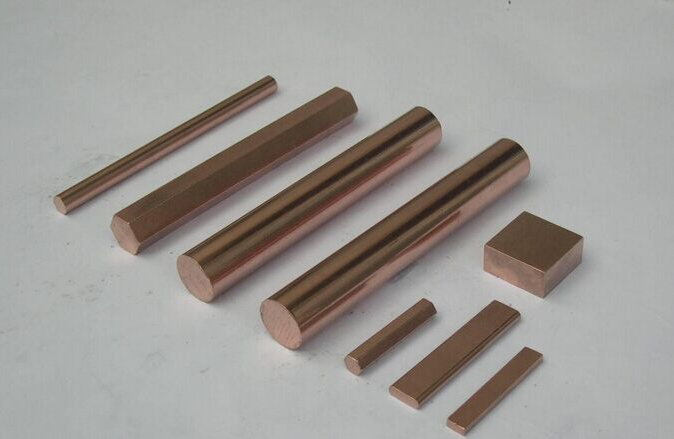

Parts are made from the CuW composite by pressing the tungsten particles into the desired shape, sintering the compacted part, then infiltrating with molten copper. Sheets, rods, and bars of the composite mixture are available as well.

Commonly used copper tungsten mixtures contains 10–50 wt.% of copper, the remaining portion being mostly tungsten. The typical properties is dependent on its composition. The mixture with less wt.% of copper has higher density, higher hardness, and higher resistivity. The typical density of CuW90, with 10% of copper, is 16.75 g/cm3 and 11.85 g/cm3 for CuW50 . CuW90 has higher hardness and resistivity of 260 HB kgf/mm2 and 6.5 µΩ.cm than CuW50.

Tungsten Copper Alloy characteristics:

Tungsten Copper Alloy has good electric conductivity, excellent high temperature strength and plasticity.

Tungsten Copper Alloy applications:

Tungsten Copper Alloy is applied to make Cu-W Alloy Threaded Rod, sealed cap for transistors sealing welder, contactor materials for high voltage switches and electrodes for spark-erosion machine tool, etc.

The Chemical Compositions and Main Properties of Tungsten Copper Alloy in Chinese National Standard GB/T 8320-2003:

| Chemical Composition(%) | Density (g/cm3) |

Hardness (HB) |

Resistivity (μΩ·cm) |

IACS% | Bending strength Mpa |

||

| W | Cu | Other | |||||

| 70±2 | 30±2 | ≤0.5 | ≥13.80 | ≥175 | ≤4.1 | ≥42 | 790 |

| 75±2 | 25±2 | ≤0.5 | ≥14.50 | ≥195 | ≤4.5 | ≥38 | 885 |

| 80±2 | 20±2 | ≤0.5 | ≥15.15 | ≥220 | ≤5.0 | ≥34 | 980 |

| 85±2 | 15±2 | ≤0.5 | ≥15.90 | ≥240 | ≤5.7 | ≥30 | 1080 |

| 90±2 | 10±2 | ≤0.5 | ≥16.75 | ≥260 | ≤6.5 | ≥27 | 1160 |

Our density:

| Type | Density (g/cm3) |

| CuW70 | 14.3 |

| CuW75 | 14.9 |

| CuW80 | 15.6 |

| CuW85 | 16.4 |

| CuW90 | 17.3 |

It is easy to find out that the density of our products is much higher than the National Standard GB/T 8320-2003. The high-density shows the processing technology of our products is superb. Density also plays an important role in loss rate and service life of product.

Aceon is the biggest Cu-W alloy suppliers in China. Our Tungsten Copper Alloy supplied for Porsche, Volkswagen and other top enterprises in the world. The market share of tungsten copper alloys in Germany is up to 30%.