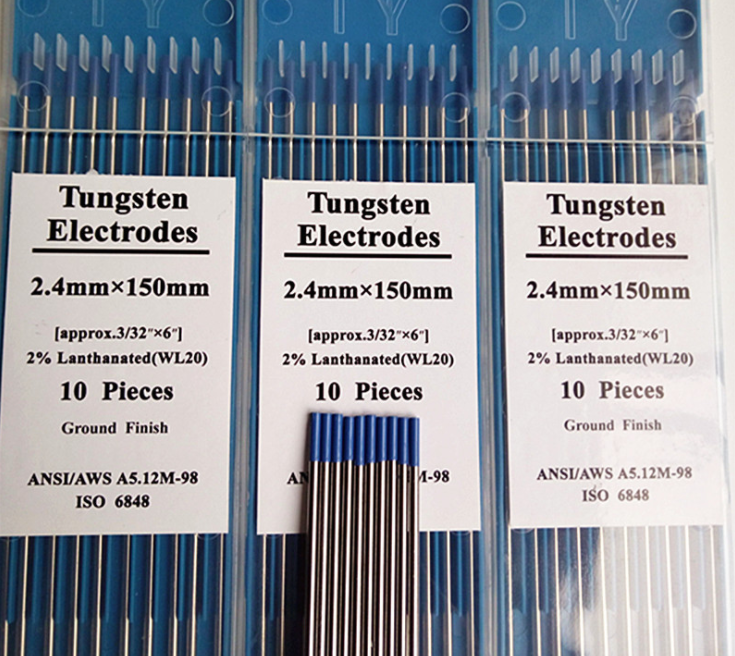

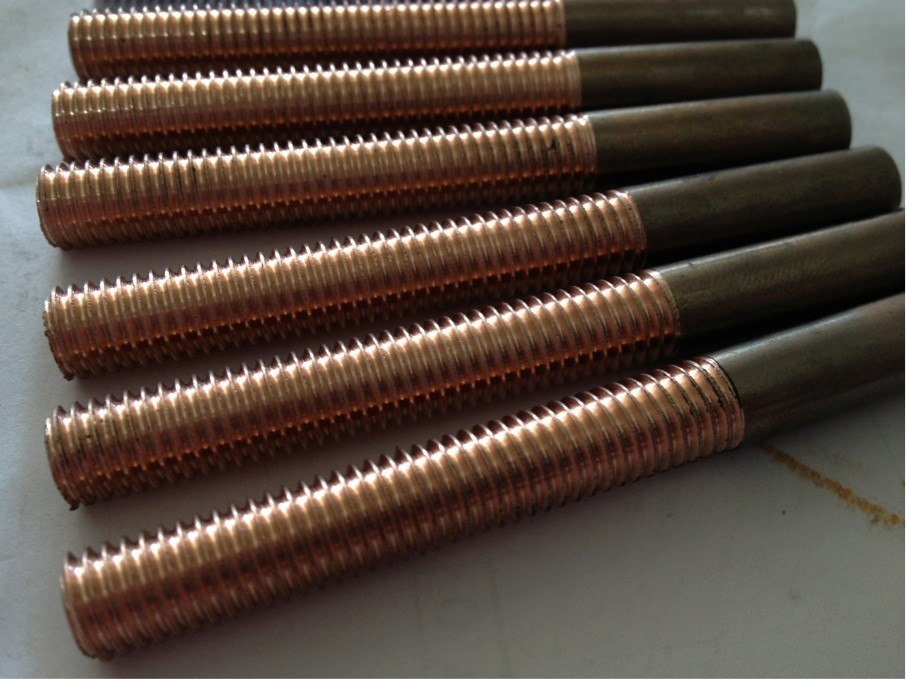

2% Lanthanated Tungsten Electrode Rod

2% Lanthanated Tungsten Electrode Rod is an ideal substitute for tungsten thorium alloy. It is a wonderful product for TIG welding.

2% Lanthanated Tungsten Electrode Rod is an ideal substitute for tungsten thorium alloy. It is a wonderful product for TIG welding.

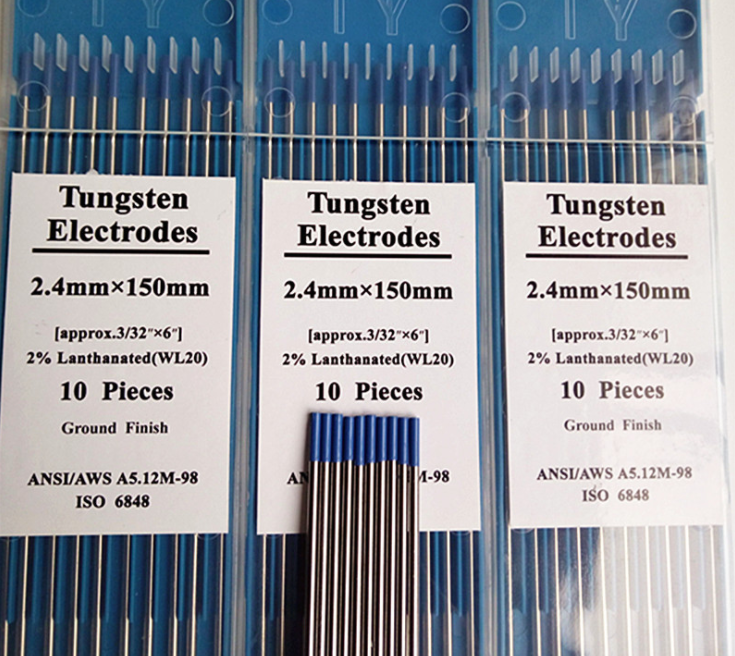

Molybdenum rod is usually used as components in electron vacuum devices, gas tube and bulbs with purity requirement. Molybdenum rod also can be used as grid siderod, support of electron tubes and lamps.

Tungsten crucible is widely used to the sapphire growth furnaces, quartz glass melting furnace, crystal furnace, induction furnace, sintering metal mold of high melting point, electronic beam coating, and rare earth smelting furnace.

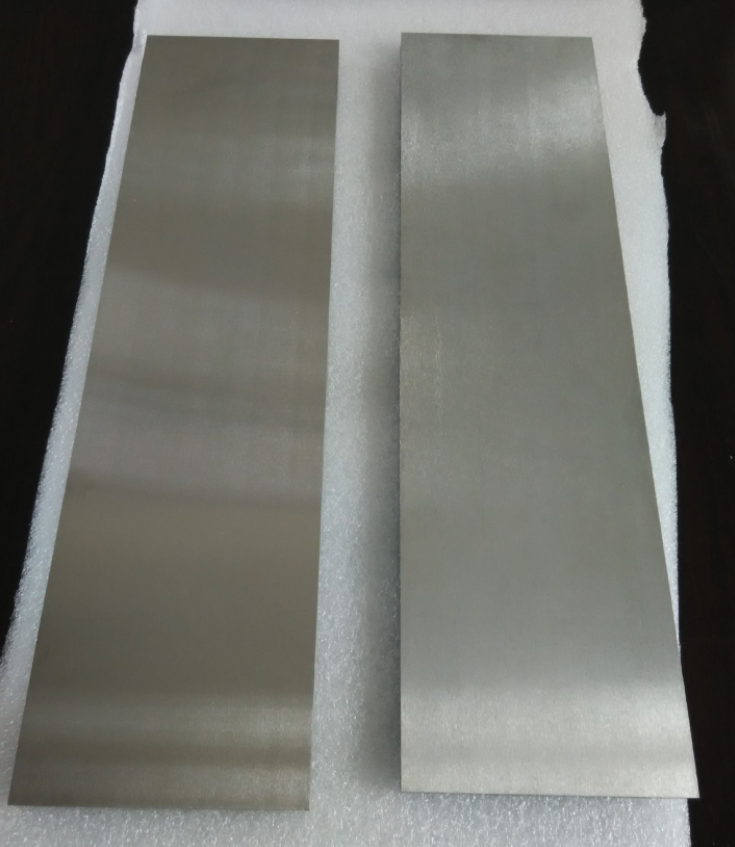

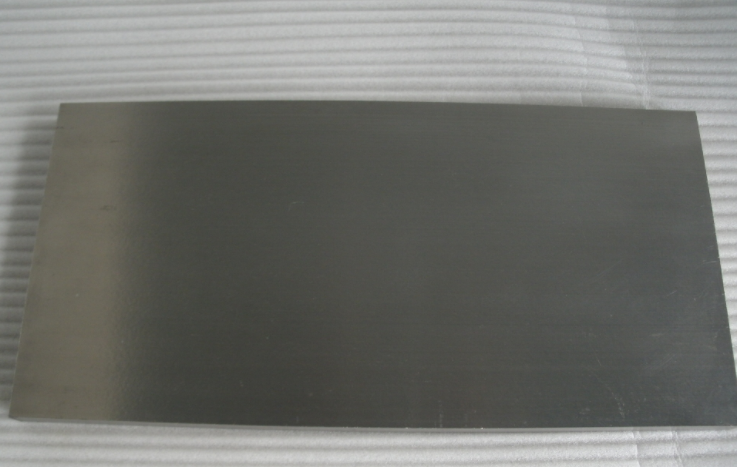

As we all know, tungsten belongs to refractory metal. Tungsten plate is machined on the basis of tungsten. It is featured by high intensity and hardness, good abrasion resistance and excellent comprehensive mechanical properties. Tungsten plate alloy is widely applied in cutting tools and mining tools.

Our molybdenum crucible is characterized by stable quality, strong anti-oxidation, anticorrosion, high temperature resistance, quick heat conduction, high efficience. Moreover, the serve life is three to five times than the common domestic crucible.

Molybdenum plate can be produced from molybdenum powder under special processing. It is made by squeezing, forging and rolling.Molybdenum plates are widely used in lighting and vacuum electric devices, electric power semi-conduction devices, heating bodies, heat shields, molybdenum boats, molybdenum crucibles and others.

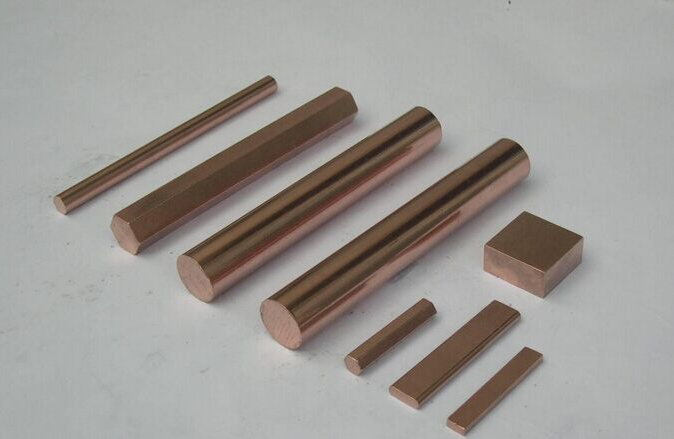

Cu-W alloy, also called tungsten-copper alloy. It is common to adopt powder alloy technology to make of Tungsten Copper Alloy. The process includes powder mixing, pressing to shapes, sintering and cold processing. With 22 years experience in dealing refractory metal, we have our own factory and perfect production line.

Tungsten material having the highest melting point, good electric conductivity, excellent thermal conductivity and a uniquely low thermal expansion and a very high level of dimensional stability.

After high temperature heat treatment, HTM still has good toughness in room-temperature. Due to the dispersion strengthening of rare earth oxide, the tensile strength of high temperature molybdenum wire is greatly improved.

Aceon is the biggest Cu-W alloy suppliers in China. Our Tungsten Copper Alloy supplied for Porsche, Volkswagen and other top enterprises in the world. The market share of tungsten copper alloys in Germany is up to 30%.