Manufacturing process:

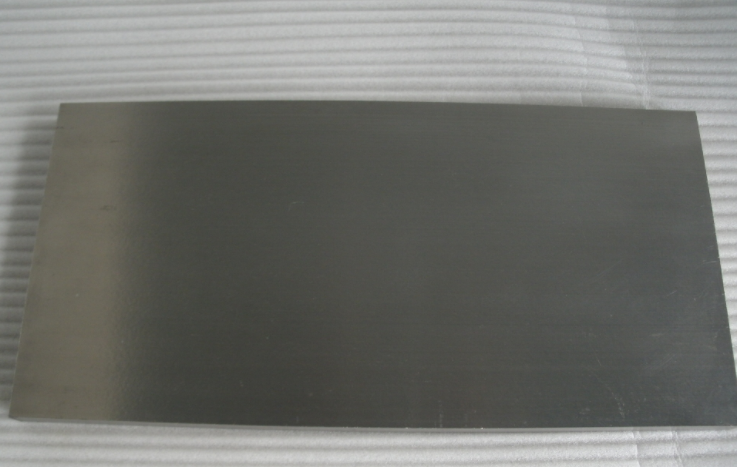

Manufacturing process of moly plate is similar to that of molybdenum sheet. Molybdenum plate is produced by shaping, sintering, hot rolling and polishing.

Cold-rolled molybdenum plate is mainly used in electric vacuum and electric light source industries.

Features of Molybdenum Plate

With the features of high melting point, high creep resistance and low thermal expansion, uses of molybdenum is to make moly plate, molybdenum alloy sheet, molybdenum rod, molybdenum wire and etc. Molybdenum plate can resist corrosion and is used to produce many special steels.

With the development of modern high temperature ceramics and electronic industry, the demand for cold-rolled moly plate is increasing. In addition, the quality requirements for cold-rolled moly plate is strict.

Applications:

Molybdenum plate can be produced from molybdenum powder under special processing. It is made by squeezing, forging and rolling.Molybdenum plates are widely used in lighting and vacuum electric devices, electric power semi-conduction devices, heating bodies, heat shields, molybdenum boats, molybdenum crucibles and others.

Moly plates also commonly used in molybdenum electrodes, vacuum furnace, nuclear energy, missile and aircraft spares.

The specifications and sizes of moly plate, we could offer according to your specific requirements, and the application environments and the the operating temperatures.

Specifications:

| Delivery condition | Size(mm) | ||

| thickness | width | length | |

| cold rolled(Y) | 0.10-0.70 | 50-600 | 100-130 |

| stress relief annealing(m) | 0.10-0.70 | 50-600 | 100-130 |

| hot rolled | >0.70-5.0 | 50-600 | >100 |

| cold rolled(Y) stress relief annealing(m) | 0.10-0.70 | 50-600 | 50-400 |

Chemical compositions

| Type | Chemical composition(%) | |

| Mo | Impurity | |

| Mo1 | >=99.95 | <=0.05 |

| Mo2 | >=99.9 | <=0.10 |

Dimensions and tolerance:(mm)

| Thickness | Width | Length |

| 0.1-0.15 | ||

| >0.30-0.30 | 50-250 | 100-1000 |

| >0.30-0.50 | ||

| >0.50-0.70 | ||

| >0.70-1.0 | 50-800 | |

| >1.0-2.0 | ||

| >2.0-3.0 | ||

| >3.0-4.0 | ||

| >4.0-5.0 |

Please note that commonly the thickness less than 1.0 mm we call molybdenum sheet and thickness more than 1.0 mm we call molybdenum plate. We could offer the custom tailored service, please contact us with your list of requirements.

Properties of molybdenum plate:

The hot or cold rolled molybdenum plates made from Aceon has good processing properties, better surface quality and good comprehensive properties.

This was just what i was searching for on this subject. Thank you!

Wow ! Thats worth a read. Thanks for writing it for us! Much appreciated

It is not my first time to go to see this web site, i am browsing this site dailly and obtain fastidious information from here.